We Offer Revolution Of Industrial & Energy Solutions

Industrial IoT Solutions.

Industrial iot solutions in Saudi Arabia

Industrial ​Internet of Things (IIoT)

In every industry, there are differences in requirements and requirements vary from one another. Our IoT-based solutions are customized according to each client’s requirements since we understand the industry requirements.

The Industrial Internet of Things bridges the gap between legacy industrial infrastructure and modern technologies such as edge computing, machine learning, cloud computing, and mobile. In order to increase productivity and efficiency, IIoT helps industries optimize industrial operations. It will enable industries to optimize their operations through the IoT, which is a disruption in industrial technology.

We build custom IOT applications based on your needs for all types of sensors, such as flow meters, power meters, temperature sensors, pressure sensors, and gas sensors. RS485-compatible third-party sensors can be incorporated into our system.

Industrial iot solutions

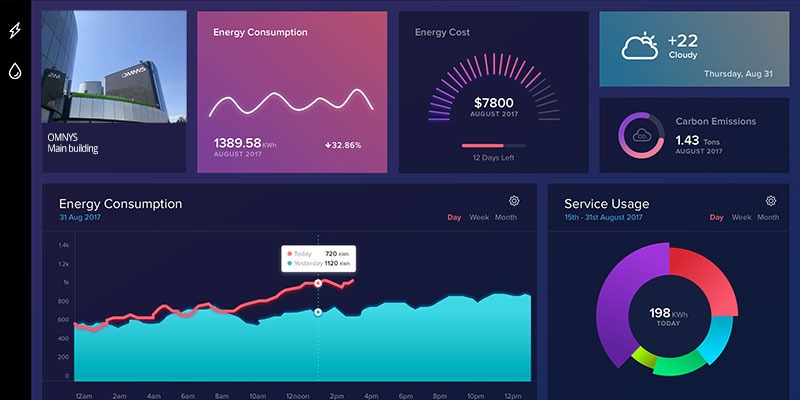

​Energy Monitoring System

Smart energy monitoring system technique tracks the use of energy of different areas of the plant throughout the day. Energy monitoring system is the most significant in demands to decrease the energy expenditure from the businesses.

Multiple energy meters is closely linked to an RS485 network. Data logger is used to get these data from energy meters through RS485 protocol. The energy monitoring system is achieved through the use of energy meters, along with data loggers.

The data plays essential part to understand the behavior of energy consumption and also to rectify and learn the undesirable energy use in the business.

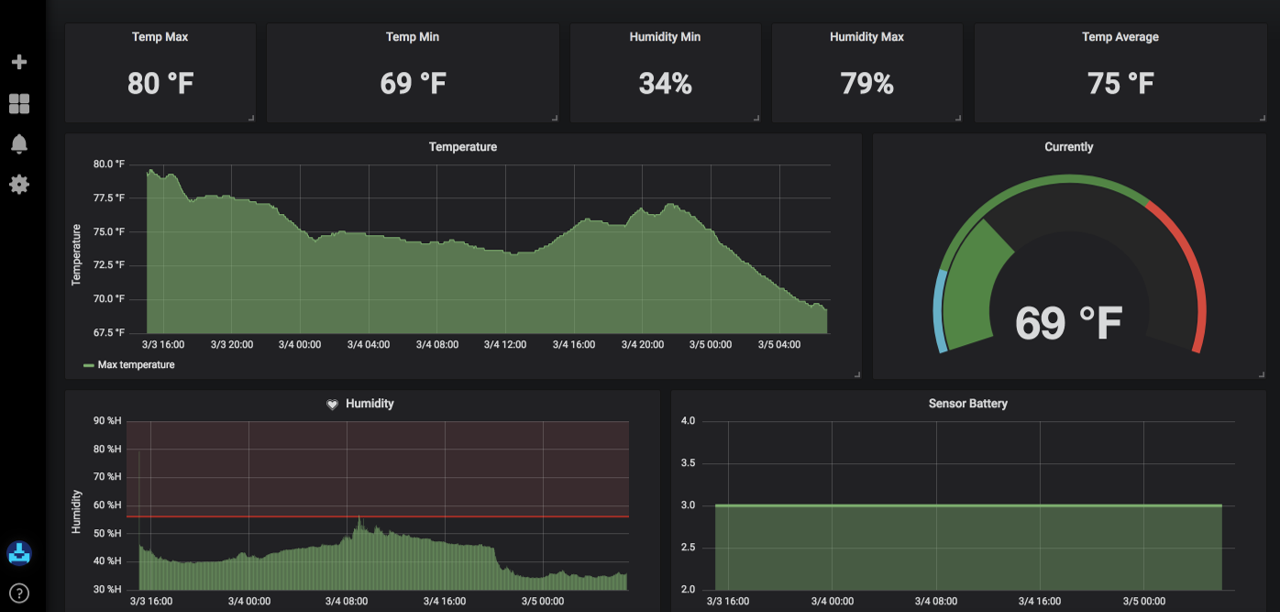

Temperature Monitoring System in Critical Area

The percentage of relative humidity in air, Co2, VOC and other environmental components. Real time live continuous monitoring system is ideal and needed for both light and heavy industrial environments.

Temperature-controlled rooms like server rooms, battery rooms, cold rooms, freezer rooms, refrigerators and freezers are tracked by air temperature monitoring systems and devices.

IoT and datalogger help you to find insights and analytics of the historic data. There are intrinsically safe devices for hazardous/explosive areas.

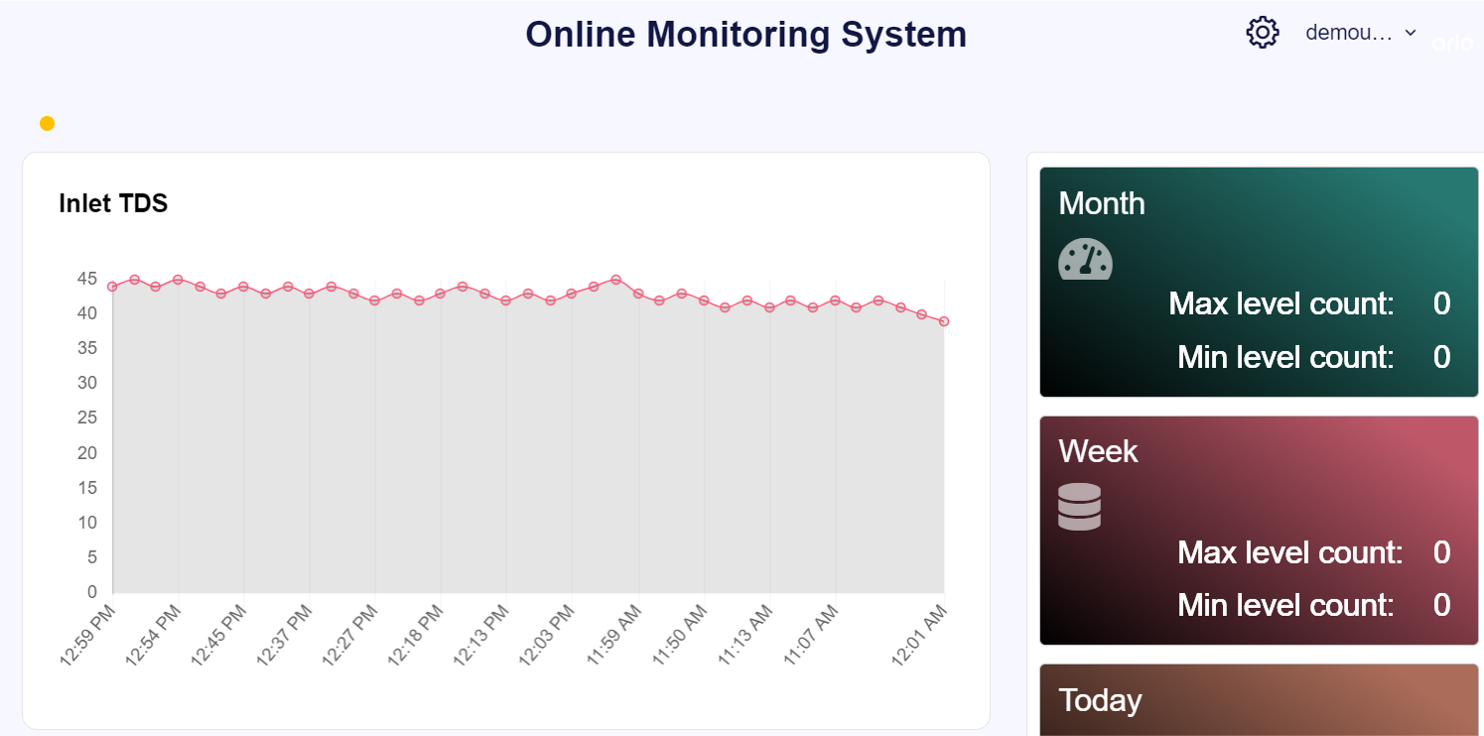

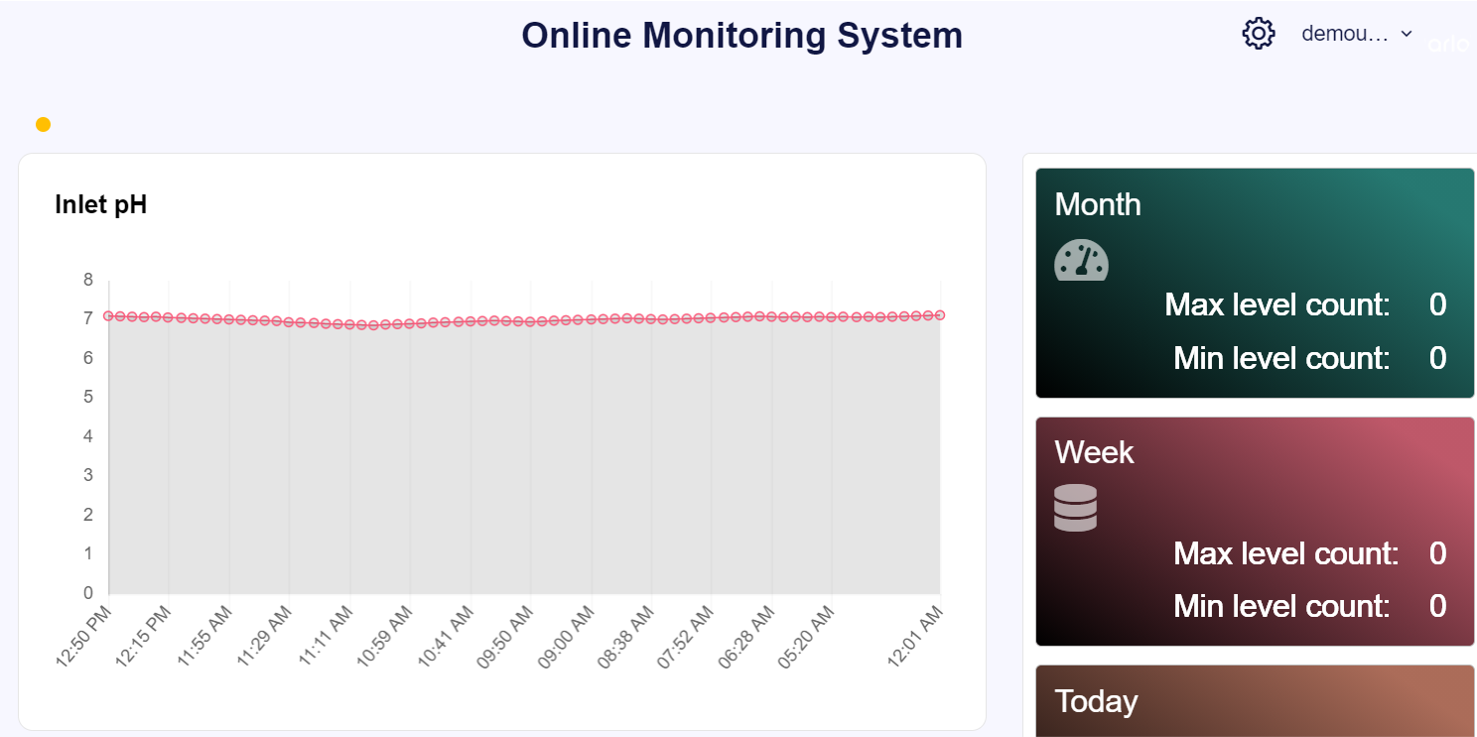

Effluent Monitoring System

Online effluent monitoring systems provide continuous analytics of data for long periods of time at the monitoring the place of interests.

With the insights of data necessary or precautionary actions can be taken to deal with excess discharge collection, preservation, transportation, sample pre-treatment, calibration, reagent addition and sample analysis procedures are usually automated in on-line analyzers are all the major steps in traditional analytics.

Real Time: Analysis

analyze your data even if you are facing the project complexity, from different overall consumption to in deep-sub-meeting.

the energy monitoring system is achieved through the use of energy meters, along with data loggers. Multiple energy meters is closely linked to an RS485 network. Data logger is utilized to get these data from Energy meters via RS485 protocol.

Finally, these electrical energy consumption associated data is processed, analyzed and reflected within datalogger then data logger transfer it’s data to LAN or cloud server. Authorised staff can have the access to the data. The data plays an essential part to understand the behavior of energy consumption and also to rectify, learn and understand the undesirable energy use in the business.

System Benefits

The best way to boost digital transformation is by using a proven track record industrial IoT platform that’s tailored made for you. An established platform offers an array of advantages

Maximize

Revenue

Scale to new markets, improve throughput, and unlock new business models such as products as a service.

Reduce Time

Get to market faster with rapid application development. Use industrial Internet of Things platforms to wrap and extend legacy assets for new functionality.

This is the heading

Harness data from connected products and systems to boost productivity and efficiency while lowering costs.

Improve Quality

Make product, service, and factory operations more secure and scalable. Improve service quality, reliability, and satisfaction.

End to end solutions

You are looking for solutions to your problems, where IOT elements are part of these solutions. Momentum end-to-end industrial IOT solutions which provide to the critical need of your business needs.

Pre-Configured Industry Vertical Business Solution

IOT business solutions is a standardised business solution is pre-configured and ready to use for variety of industries vertical and can be implemented within 4-6 weeks. Momentum is customisable to all your needs according to the specific needs of industries

Modular, Flexible, Scalable & Standardized

IOT business solution is a standardised business solution, IOT solution is scalable and flexible enough to meet changing demand of industries with scalable and secure modular solutions

Learning and Automated Data Pattern Recognition

The in built domain specific learning and automated data pattern recognition system, which are standard with IOT solutions are specifically made to tailor to meet individual business needs